Blueprints to Chips: CAD/CAM Tips and Tricks

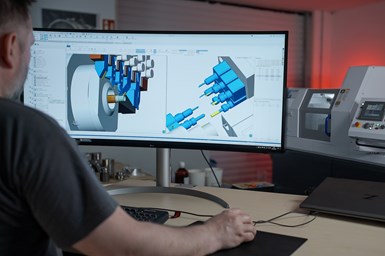

This collection of articles delves into the latest CAD/CAM innovations, from AI-driven automation and optimized tool paths to the impact of digital twins and system requirements.

Share

In the ever-evolving world of metalworking and CNC machining, CAD/CAM software plays a crucial role in transforming digital designs into precise, high-quality parts. From optimizing tool paths and automating programming to leveraging artificial intelligence (AI) and digital twins, these articles explore the latest software and AI advancements shaping the future of machining. Whether you're looking to improve efficiency, adopt new technologies, or understand system requirements, this collection covers key insights to help manufacturers stay ahead in our increasingly digital landscape.

Generative Design for Milling Lightweights EV Motorbike Part

Here’s how Autodesk’s Fusion 360 generative design function aims to provide mass-saving solutions for three-axis milling and other conventional manufacturing processes.

Can the manufacturing world achieve gains in part-programming productivity and flexibility with machine-aware, smart digital twins powered by AI? Hexagon thinks so.

Cutting Part Programming Times Through AI

CAM Assist says it can cut repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers. Here’s how.

According to TK, overall machining efficiency can be increased when software and tooling companies combine to tackle machining challenges. Read how it’s done.

Advanced Tool Paths, Simple Implementation

Programming advanced tool paths used to be a complex, time-consuming task. Here’s how canned cycles in CAM software have now made them more accessible than ever.

SolidCAM aims to align its product development and customer engagement strategies to address the evolving needs and challenges of the manufacturing industry.

Can ChatGPT Create Usable G-Code Programs?

.Source: CAMInstructor

Since its debut in late 2022, ChatGPT has been used in many situations, from writing stories to writing code, including G-code. But is it useful to shops? We asked a CAM expert for his thoughts.

This manufacturer of high-end RC cars leverages the capabilities of its CAD/CAM software to get the most out of its first Swiss-type lathe even when job batch sizes are relatively low.

CAD/CAM System Requirements: An Overview

CAD/CAM programs are among the most demanding kinds of computer software. Smooth operation requires careful consideration of computer specifications, including these.

This toolpath generator aims to reduce cycle time and extend tool life while helping achieve better surface finishes for milling operations on multi-axis Swiss-types and turn-mills.

Related Content

-

How this Job Shop Grew Capacity Without Expanding Footprint

This shop relies on digital solutions to grow their manufacturing business. With this approach, W.A. Pfeiffer has achieved seamless end-to-end connectivity, shorter lead times and increased throughput.

-

Give Job Shop Digitalization a Customer Focus

Implementing the integrated digital technologies and automation that enhance the customer's experience should be a priority for job shops and contract manufacturers.

-

Four Questions (& Answers) About Data-Driven Process Improvement at CNC Job Shops

How can shops can make informed decisions using data-driven feedback to improve shopfloor efficiency and profitability? And how will these technologies differ between high- and low-volume production?