Robots and Automation in 91ĘÓƵ

Machine-tending robots are often key components used to enable unattended or lights-out machining operations, adding capacity by taking advantage of time that’s currently unused, like nights and weekends. In many cases, robot integration enables shopfloor employees that were previously loading and unloading parts from machines to perform duties of greater value. Plus, today’s robots are faster and more intelligent than in years past and are also becoming increasingly viable for small-batch/high-mix production. In addition, collaborative robots, or “cobots,” use sensor technology that enables them function safely alongside humans in a shared work environment. That means no more isolating fencing is needed to separate worker and robot.

ESSENTIAL READING

VIEW ALL4 Manufacturing Trends That Cannot Be Ignored

The next five years will present their own unique set of challenges, and shops can alleviate them by embracing these technologies and trends.

Read MoreBlueprints to Chips: CAD/CAM Tips and Tricks

This collection of articles delves into the latest CAD/CAM innovations, from AI-driven automation and optimized tool paths to the impact of digital twins and system requirements.

Read More4 Steps to a Cobot Culture: How Thyssenkrupp Bilstein Has Answered Staffing Shortages With Economical Automation

Safe, economical automation using collaborative robots can transform a manufacturing facility and overcome staffing shortfalls, but it takes additional investment and a systemized approach to automation in order to realize this change.

Read MoreMade in the USA - Season 1 Episode 2: The Automation Puzzle

There is a fundamental question we need to answer when we talk about automation: To what extent is automation an answer to the skilled workforce shortage, and to what extent is automation vs. Skilled labor the wrong comparison to make in the first place?

ListenChoosing a Five-Axis Machine Tool With Automation in Mind

While much focus is placed on the machinery that moves parts, the features most important for automating five-axis machining are arguably found in the machine tool itself.

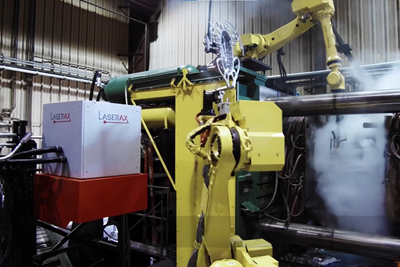

Read More5 Tips for Automating Laser Marking With Robots

Automating laser marking can be a useful way to increase robots’ utilization, but the process requires careful planning for success.

Read MoreLatest Automation News And Updates

Royal Products Rotary Accumulator Boosts Machine Utilization

PMTS 2025: The Rota-Rack Compact automatic rotary accumulator is designed specifically for small parts and Swiss applications.

Read More3 Machine Options to Aid Automation

Don’t overlook controller options, process security options and coolant handling when staring down the line items of a new machine purchase.

Read MoreKUKA Automation Tech Day Highlights the Power of Integrated Automation Technologies

A demonstration of an automated machining cell showed the power of combining vision systems, robots and AMRs.

WatchSMW Autoblok Promotes Sales Lead for Automation, Electronics

John Andrick will support customers with electronic solutions designed to optimize automation processes and enhance robotic applications to support the evolving industry demands.

Read MoreThree Features That Maximize Unattended Machining on Palletized Machines

Probing and laser systems, large tool magazines, and pallets with multiple parts enable users to run pallet systems for longer periods of time, increasing spindle uptime.

Read MoreABB Robotics Software Reduces Setup Times

AppStudio is designed to provide flexibility and ease of use for creating customized robotic user interfaces.

Read MoreFeatured Posts

The Four Phases of a Manufacturer’s Automation Evolution

With more and more automation options available for manufacturers, how do shops figure out what works best? Medical manufacturer rms Company has acquired robot arms, AGVs, pallet changers and software, and while it has found success with all, it has learned how some solutions meet its particular needs better than others.

Read MoreWhy We Ask Machine Shop Leaders to Speak at TASC – The Automated Shop Conference

TASC is our industry’s premier peer-to-peer automation stage where America’s shop leaders refine the art of metalworking and CNC machining. For conference speakers, it's also an opportunity to showcase your skills and gain exposure for your business. Here are five why stepping into the spotlight at TASC could be your smartest move toward elevating your shop.

Read MoreJIMTOF 2024 Report: EVs, AI and Autonomous Robots Abound

The 2024 Japan International Machine Tool Fair (JIMTOF) showed how the manufacturing industry is adapting to the needs of electric vehicle manufacturing and adopting new technology including AI and autonomous robots.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreMeasuring Torque, Thrust Force for Smart Drilling Operations

To monitor drilling operations for smart manufacturing solutions, torque and thrust force can be measured.

Read MoreFAQ: Automation

What is automation?

“Robot” is the first picture that comes to mind, but it means more than that. Automation could be machines that are able to do more in one setup, one handling. It also refers to other options like pallet systems for moving work around, in and out of machines. It refers to software that can automate certain operations. Automation is not a replacement or an alternative for people.

What is a cobot?

A collaborative robot or “cobot” is a robot that is safe to run unguarded near people. Most cobots are safe because they are speed- and force-limited, and they stop upon sensing contact with an obstacle. Cobots are also easy to relocate and reprogram for different tasks in a shop.

What should you know about cobots?

1. Cobots, vision and AI all go together.

2. Cobots do not guarantee safety.

3. Cobot applications need not feature collaboration.

4. Automation’s payback period is declining.

5. Trends in manufacturing favor collaboration.

6. Cobot adoption might be held back by lack of people.

7. Advancing AGV technologies make cobots mobile.

8. Attention recognition is coming.

9. Collaborative can be done in different ways.

10. “Collaborative” can be a bigger idea.

How do robots and 3D printing intersect?

1. 3D Printed End-of-Arm Tooling (EOAT)

2. 3D Printed Off-Robot Accessories

3. Robot-Tended 3D Printers

4. Robots As 3D Printing Systems