Five Go-To Machining Technologies

There are a number of ancillary machine tool technologies that shops can use to become more efficient and effective. Here are five that I appreciate.

Share

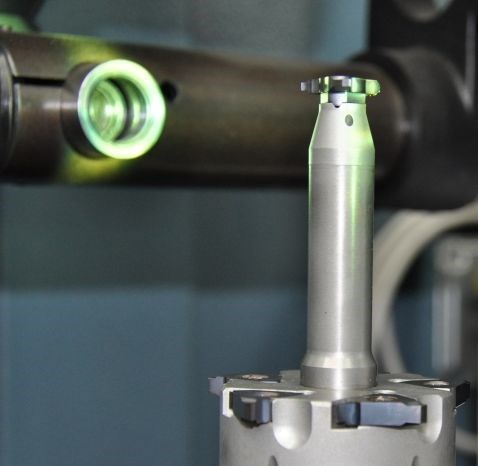

Toolholder assemblies for an upcoming job can be measured in seconds using a presetter, without the machine being interrupted.

We all know what opinions are like. That said, I thought of five pieces of ancillary machining equipment that I feel many shops can leverage to their success:

- Tool vending systems

- Tool presetters

- Machine tool probes

- High-pressure coolant delivery

- Shopfloor CMMs

Related Content

-

Medical Shop Performs Lights-Out Production in Five-Axes

Moving to five-axis machining enabled this shop to dramatically reduce setup time and increase lights-out capacity, but success relied on the right combination of workholding and automation.

-

The Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

-

Shoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.