Know About the “Headless Bolt” Fixturing Alternative?

This fastener enables fast workpiece change-overs compared to conventional bolts. Its compact design means there’s less cutter interference, too.

Share

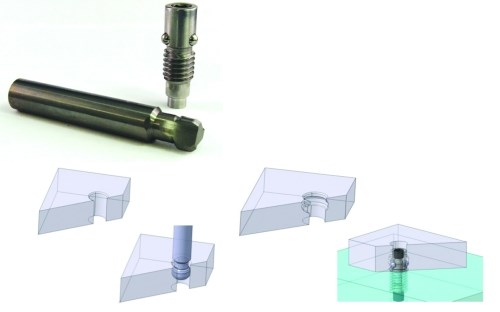

Loc-Down units install in tapped holes in a subplate. The workpiece (shown here in gray) requires mating holes that have a machined internal groove to accommodate the units. Holding force is provided via the unit’s ball-lock mechanism.

Installing and removing conventional bolts used to secure workpieces to subplates can be time-consuming. Plus, protruding bolt heads often interfere with the cutting tool, preventing it from accessing all workpiece areas that require machining. As a result, has developed its “headless bolt” Loc-Down system so users can quickly attach and remove workpieces from subplates. Not only does this system enable faster workpiece change-overs compared to conventional bolts, but there’s less cutter interference thanks to its compact design. Learn more.

Related Content

-

Quick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

-

How to Troubleshoot Issues With Tool Life

Diagnosing when a tool is failing is important because it sets an expectation and a benchmark for improvements. Finding out why gives us a clue for how to fix it.

-

Briquetting Manufacturer Tools Up for Faster Turnaround Times

To cut out laborious manual processes like hand-grinding, this briquette manufacturer revamped its machining and cutting tool arsenal for faster production.