Racing Toward the Intersection of Design and Manufacturing

Driven by software automation and with all engineering and production under one roof, this drag racing organization provides a striking example of a machining operation with data at the center.

Share

As detailed in our coverage of Autodesk University (AU), Autodesk’s annual user conference in Las Vegas, Nevada, automation—particularly software automation—is democratizing product development and driving the convergence of engineering and manufacturing. For manufacturers, there was another message as well: There’s no need to wait for some distant future to start putting data at the center of the operation. That is, to define the business by the design and/or manufacturing process information that makes a company different, rather than the tools used to work with that data.

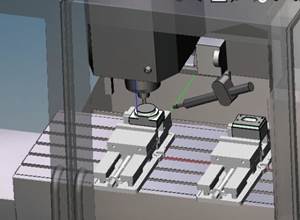

What, exactly, does it look like for a machining operation to put data at the center? Tim Evans, a guest speaker from drag racing organization Kalitta Motorsports, provided a striking example.

Granted, few machine shops are in the business of racing, but Mr. Evans outlined how constantly changing parts leads the organization to face similar challenges as any contract machining operation. Consider the clutch assembly, which must be tuned according to racing conditions (for instance, a hot track tends to be more slippery). The fact that these conditions change regularly, not to mention the stress of speeds exceeding 300 mph, leads teams like Kalitta to rebuild assemblies between every race. This involves a significant amount of titanium machining, with one component weighing in at almost 100 pounds and measuring 14 inches in diameter. Getting these assemblies into the cars on time requires end-to-end efficiency, from finalizing designs to machining the parts.

Mr. Evans described why changes in software capability have been so essential to that end-to-end efficiency. It started in 2014 with a move to Inventor HSM. Specifically, with the CAM system’s “adaptive” tool paths, Autodesk’s variety of the light, fast, constant-engagement strategies that are widely replacing slower, heavier cuts. The resulting improvements in tool life and performance have reduced machining time on main clutch components from 30 hours to 10.

And yet, the tool paths themselves weren’t what “sealed the deal,” as Mr. Evans put it, after evaluating the subscription-based software in a free trial. He reserved that phrase for full CAM integration and associativity, via the AnyCAD link, with Inventor’s CAD design functionality. “The ability to make changes, work directly on the solid model, and instantly update toolpaths all in the same software—it worked like magic,” he said. “Our designs are at the center of our work, and we can move them easily between software,” he continued, adding that this includes legacy parts originally modeled in Solidworks.

However, the team hasn’t stopped with the ability to work with model and part program as one and the same entity. He went on to explain how it’s also beginning to explore the possibilities of Autodesk’s Generative Design service. Previously available only to users of Netfabb Ultimate, a tool dedicated to modeling for additive processes, the technology is now being rolled out to Fusion 360 subscribers like Kalitta. In essence, generative design leverages the power of modern computers to generate multitudes of basic design possibilities in an instant, all based on specific constraints issued by the designer. For instance, a drag racing team’s constraints are likely to include not just dimensions and materials, but also specifications to ensure parts are both strong enough to withstand the pressures of the track and light enough to provide a competitive edge.

From there, part performance can be simulated using finite element analysis (FEA) and computational fluid dynamic (CFD) technologies. This is both faster and more cost effective than real-world wind tunnel and other testing that, ironically, can potentially involve more results-distorting variation than computer simulations.

Our coverage of Autodesk University offers more detail on the latest CAD/CAM developments, not to mention generative design, automated and virtual reality, simulation and other technologies that are shaping what the software developer calls “The Future of Making.”

Related Content

TTI Brings Specialty Gear Production In-House with Multiaxis Machining

By investing in a 3+2-axis machine and utilizing simulation software for diagnostic checks, Techtronic Industries turned a four- to ten-week lead time into a one- to two-week lead time.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreAdvanced Tool Paths, Simple Implementation

Programming advanced tool paths used to be a complex, time-consuming task. Canned cycles in CAM software have now made them more accessible than ever.

Read MoreHow Integrated CAD/CAM Transforms Inventions Into Products

The close connection between CAD and CAM is what links creative ideas to practical production for this unique custom manufacturer.

Read MoreRead Next

Machine Shop MBA

Making Chips and Modern Machine Shop are teaming up for a new podcast series called Machine Shop MBA—designed to help manufacturers measure their success against the industry’s best. Through the lens of the Top Shops benchmarking program, the series explores the KPIs that set high-performing shops apart, from machine utilization and first-pass yield to employee engagement and revenue per employee.

Read MoreAMRs Are Moving Into Manufacturing: 4 Considerations for Implementation

AMRs can provide a flexible, easy-to-use automation platform so long as manufacturers choose a suitable task and prepare their facilities.

Read More