The Basics of Bar Pullers

Bar pullers are cost-effective alternatives to enable automated turning on CNC lathes. Learn how they work and how shops can benefit from using them.

Share

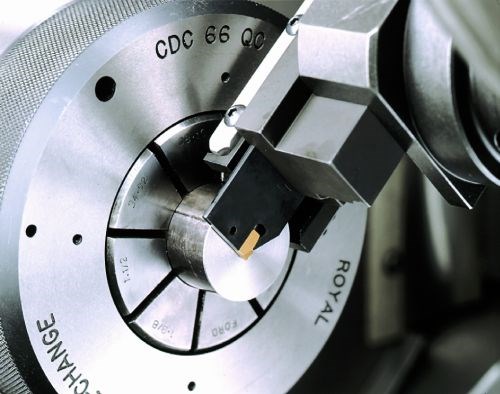

This combination bar pulling unit incorporates a cutoff tool so it occupies only one lathe turret station and eliminates an index from tool to puller.

There are multiple ways to automate a CNC lathe. If your goal is to gain lengthy stretches of unattended operation, then a bar feeder is hard to beat. Conversely, a bar puller is a cost-effective alternative for automated turning of small or medium batch sizes. That’s because a puller can free up sufficient time between bar changes to enable a single operator to tend multiple machines, measure critical part features or perform value-adding secondary operations. The resulting labor cost savings can quickly pay for the puller, as explained in this past article.

Related Content

-

3 Ways Artificial Intelligence Will Revolutionize Machine Shops

AI will become a tool to increase productivity in the same way that robotics has.

-

Same Headcount, Double the Sales: Successful Job Shop Automation

Doubling sales requires more than just robots. Pro Products’ staff works in tandem with robots, performing inspection and other value-added activities.

-

Using Automation to Reduce COGS and Stay Globally Competitive

Decade-long, multiphase automation investments lower operating costs and maintain technology lead in an increasingly competitive global market.