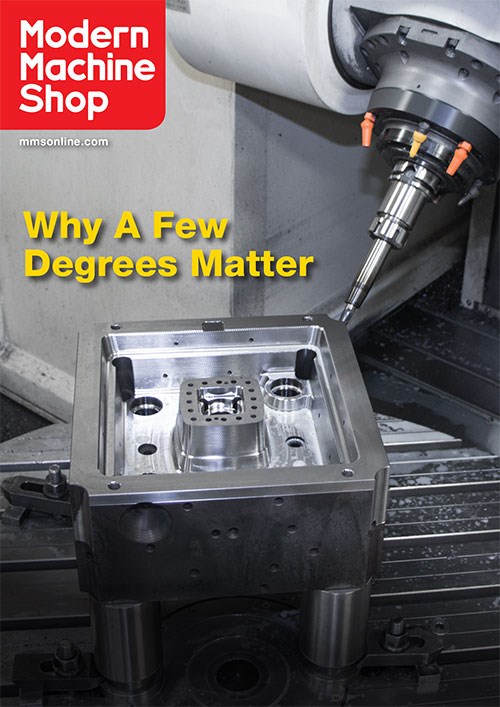

Why a Few Degrees Matter

3 + 2 machining might not be as captivating as five-axis contouring operations, but it can be just as valuable.

Share

Five-axis machines enable two types of multi-axis machining operations: full contouring and positioning (a.k.a. 3 + 2 machining). Thought of as siblings, contouring would be the alluring one and 3 + 2 would be more on the homely side. This is because contouring operations feature complex simultaneous motion of all five axes during a cut while 3 + 2 only uses the rotary axes to position and then lock the tool and/or workpiece at different angles outside of the cut.

That said, many shops find great value in 3 + 2. One is Canada’s . It now leverages 3 + 2 to manufacture more reliable and effective molds for thin-walled containers. Among other benefits, this capability has enabled it to reduce setups of mold inserts from as many as 25 to two, as detailed in this story.

Related Content

-

How to Determine the Currently Active Work Offset Number

Determining the currently active work offset number is practical when the program zero point is changing between workpieces in a production run.

-

Custom Workholding Principles to Live By

Workholding solutions can take on infinite forms and all would be correct to some degree. Follow these tips to help optimize custom workholding solutions.

-

Obscure CNC Features That Can Help (or Hurt) You

You cannot begin to take advantage of an available feature if you do not know it exists. Conversely, you will not know how to avoid CNC features that may be detrimental to your process.