Video: Music by Modulation

M4 Sciences makes a device that uses modulation-assisted machining to prevent chips from binding during deep drilling. Called ‚ÄúTriboMAM,‚ÄĚ the system oscillates the drill in and out of the cut 1,000 times per second.

Share

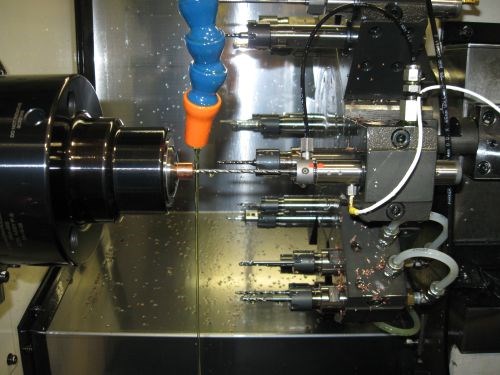

M4 Sciences makes a device that uses modulation-assisted machining to prevent chips from binding during deep drilling. Called “TriboMAM,” the system oscillates the drill in and out of the cut 1,000 times per second. One of its users is this shop: Alphatec Spine.

Previously, a small problem with this system related to confirming that the unit had activated. At full speed, its operation is not audible. How could the operator be sure it was running? This was indeed a small problem, because M4 Sciences implemented a simple solution: Running at a slower, audible frequency immediately at startup enables the unit to make a sound that users can hear.

This video shows the company taking that solution a little farther. Running at a series of frequencies creates an effect that is not only audible, but recognizeable.

In the video, the TriboMAM unit (making the music) is the cylindrical object in the foreground. The photo below shows the unit in use within a CNC lathe.

Related Content

-

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

-

Medical Shop Performs Lights-Out Production in Five-Axes

Moving to five-axis machining enabled this shop to dramatically reduce setup time and increase lights-out capacity, but success relied on the right combination of workholding and automation.

-

Toolpath Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s toolpath can dramatically improve its ability to manage chips.