CGTech's Vericut 9.1 Improves CNC Simulation Visibility Options

Version 9.1 of CGTech’s Vericut includes enhancements to toolpath optimization, additive manufacturing, tooling and multi-tool stations, and measuring and inspection.

Share

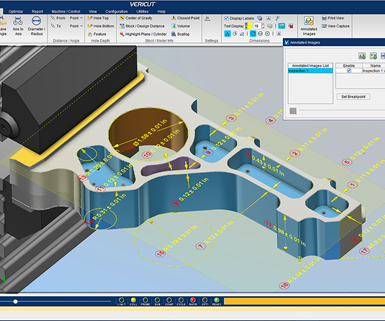

Version 9.1 of CGTech’s Vericut machine simulation, verification and NC optimization software includes new visibility options and enhancements to toolpath optimization, additive manufacturing, tooling and multitool stations, and measuring and inspection.

Visibility features added to the Project Tree and right-click menus for components and models enable users to toggle between visible and invisible states or to enable/disable 3D objects for the simulation. New features added to AUTO-DIFF likewise give users more control over component visibility, such as when fixture models should appear.

Setup Plan has been renamed Annotated Images. Vericut Inspection is also now included with Annotated Images. Both Setup Plan and inspection functionality provide dimensions, notes and tolerances for checking parts at various stages of machining. Users can create professional and informative setup plans and inspection images stored with view layouts ready to print as shop aid documents or to appear in Vericut’s reports.

Defining shanks as separate objects from the holder and cutter enables programmers to see where these non-cutting portions of the cutter are located relative to the stock workpiece, allowing for more discrete control over near-miss and collision detection properties and tolerances.

A Force “Learn” Mode is now available for optimization, which uses artificial intelligence to learn from the cutting simulation and then automatically configure and optimize tools for increased cutting efficiency and reduced machining times. A Learn From Results option enables optimization settings for a tool or all tools that were analyzed.

Vericut 9.1 has a new “Additive” Default Machining Type, enabling enables the software to predict system resources that will be needed to additively build the as-designed part, including a starting stock build plate or model. Vericut can build multiple parts created by a nested-build NC program, enabling additively built parts to be independently relocated or assembled for finish machining or exported.

Related Content

-

2 Secondary Coordinate Systems You Should Know

Coordinate systems tell a CNC machine where to position the cutting tool during the program’s execution for any purpose that requires the cutting tool to move.

-

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

-

5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.