Garant Master Steel Deep Enhances Performance and Longevity

The Hoffmann Group’s Garant Master Steel Deep tool can operate without a co-pilot hole in stainless steel and cast iron.

Share

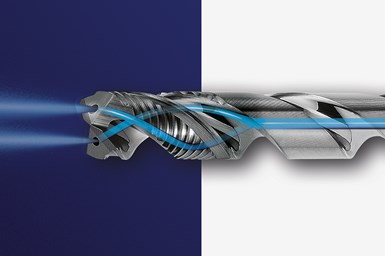

The Hoffmann Group’s Garant Master product family has expanded with the launch of Garant Master Steel Deep. The company says this deep hole drilling tool features good process reliability with high cutting parameters, operating without a co-pilot hole in stainless steel and cast iron. The tool is also said to achieve a tool life ranging to three times that of competitors.

The Hoffmann Group’s internal tests show the Garant Master Steel Deep can achieves as much as a 30% increase in metal removal rates, as much as 70% higher process reliability and around three times longer tool life over its predecessor and competitors. The tool owes its performance to straight main cutting edges, which reduce cutting forces; improved point geometry, which is designed for optimum chip breaking; and its design, which offers advantages for cooling and drill guidance. The through-cooling is only helical in the head, enabling an unequal helical pitch of the chip flutes on the remaining drill body, with an adaptive helix angle from 15 to 30 degrees. The company says this cooling design leads to swifter chip evacuation and greater process reliability at higher cutting speeds. Patented drill guidance reduces vibration and promotes top drill hole quality. Thanks to the guide rings, coolant flows around the drill tip in a targeted manner and prevents the machining zone from overheating. In addition, a head coating and polished chip flutes optimize chip flow.

The company says that the Garant Master Steel Deep’s sintered carbide substrate core and wear- and heat-resistant TiAlN-based multi-layer coating improve stability and durability. Operators can regrind the tool to its original quality as many as four times.

Related Content

-

Chuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

-

Quick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.