Haubex's Automatic Vise Change From Tool Magazine

Lang Technovation’s Haubex is a simple automation solution for small batches that transforms the tool magazine into an automation system.

Share

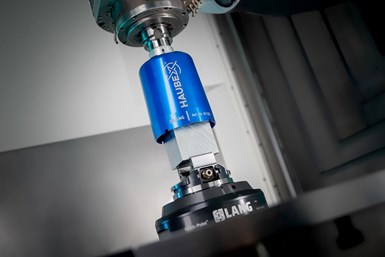

Haubex system transporting new production part. Photo Credit: Lang Technovation

Lang Technovation says its Haubex is a flexible and cost-effective for small batches from batch size 2 that transforms the tool magazine into an automation system. The heart of the system is a workholding hood, which serves as a carrier system for the clamping device and the workpiece blank and is stored in the tool magazine.

The system is said to make it easy to increase efficiency in manufacturing by productively filling breaks, creating additional time windows for alternative, value-adding activities or extending working hours by enabling the machine tool to continue unmanned production after the end of work.

Related Content

-

Rail Manufacturer Moves Full Steam Ahead with Safe, Efficient Workholding Solution

All World Machinery Supply paired a hydraulic power unit with remote operating capabilities in a custom workholding system for Ahaus Tool & Engineering.

-

Chuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

-

Using Jaws as Grippers Enables Flexible, Low-Cost Automation

VersaBuilt’s automation systems significantly boosted Innovative Fabrication’s revenue. In return, the shop has helped VersaBuilt optimize its products.