High QA's Inspection Manager 5.0 Improves Support for ISO, BSI, ASME Standards

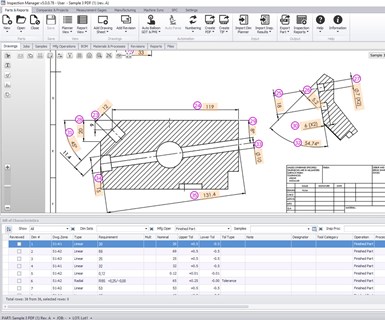

High QA’s Inspection Manager (IM) 5.0 includes features for higher quality standards and increased automation.

Share

High QA’s Inspection Manager (IM) 5.0 includes features for higher quality standards and increased automation. Designed and built as a database-driven software, IM 5.0 is an integrated set of applications, including quality management modules like One-Click geometric dimensioning and tolerancing (GD&T) extraction and automatic ballooning using advanced AI-driven OCR; inspection planning; data collection and organization; automated import of inspection results from coordinate measuring machines (CMMs), vision measuring machines (VMMs) and other connected measurement equipment; in-process shopfloor inspection results collection; creation of standard and custom forms and reports; Integrated SPC tracking and reporting; user-access security management control; ERP integration; and more.

IM creates inspection plans, balloons PDFs, consolidates results and generates reports to AS9102, Medical Industry Standards, AIAG/PPAP, and other standard or custom forms. Version 5.0 features enhanced support for metric dimensions, ISO, BSI and ASME metrology standards.

One-Click OCR GD&T extraction and ballooning from 2D drawings, PDFs, TIFF, or other image files is a fundamental component of IM. In version 5.0, that feature now includes support for surface finish and welding symbols, saving time in the initial phase of inspection planning. The software now streamlines the various modules and systems integration and maximizes automation and efficiencies to meet current and future measurement and inspection quality demands and requirements.

Enhanced job lifecycle management provides greater workflow support, managing jobs and batch records as they move from stage to stage in the process. A database upgrade addresses various installation scenarios, including external MS SQL server locations and advanced database administrator (DBA) settings.

Related Content

-

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

-

Medical Shop Performs Lights-Out Production in Five-Axes

Moving to five-axis machining enabled this shop to dramatically reduce setup time and increase lights-out capacity, but success relied on the right combination of workholding and automation.

-

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.