Hoffman Group Expands Parabolic Performance Cutting Tools

Hoffmann Group USA has expanded its Parabolic Performance Cutting (PPC) series with a set of indexable inserts and Garant PPC solid carbide barrel milling cutters for high-alloy and hardened steels.

Share

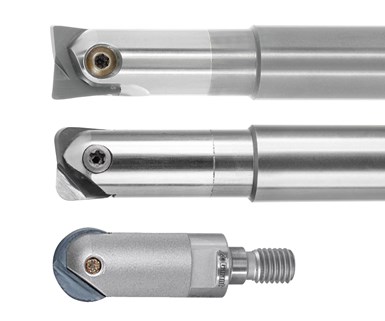

Hoffmann Group USA has expanded its Parabolic Performance Cutting (PPC) series with a set of indexable inserts and Garant PPC solid carbide barrel milling cutters for high-alloy and hardened steels. The PPC process, also known as barrel milling, is a type of ball-nosed slot drill cutting operation primarily used for finishing free-form surfaces.

Compatible with Garant copy milling cutters and tool bodies, the straight or stub point conical inserts are an alternative to PPC solid carbide cutters. According to the company, the PPC cutoff inserts effectively machine flat faces and freely accessible surfaces without interference contours in steel, high-alloy and hardened steels, stainless steel, and aluminum.

In addition to the new PPC indexable insert, the Hoffmann Group has optimized three versions of its PPC solid carbide barrel milling cutter for hard machining. The new tools have a tangential, conical or stub-point conical form and are also suitable for finishing flat faces and large surfaces with interference contours, as well as deep and hard-to-access cavities.

Related Content

-

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

-

Custom Workholding Principles to Live By

Workholding solutions can take on infinite forms and all would be correct to some degree. Follow these tips to help optimize custom workholding solutions.

-

Medical Shop Performs Lights-Out Production in Five-Axes

Moving to five-axis machining enabled this shop to dramatically reduce setup time and increase lights-out capacity, but success relied on the right combination of workholding and automation.