-

SPONSORED

-

SPONSORED

Cutting Tools

End Mills Cut at High Feed Rates in Hard Metals

Imco’s enDuro M525 end mill and its five-flute variations are designed for higher feed rates in titanium and stainless steel.

Read MoreHorizontal Boring and Milling Machine Provides Accurate Cutting

A combination of a robust design, thermal compensation and scales on axes in SNK’s Nissin HBM BHP130-3.5 series horizontal boring and milling machine is designed to produce high cutting accuracy.

Read MoreHorizontal Boring Mill Designed for Large Components

The Spirit 200 horizontal boring mill is designed for machining large components for the energy industry as well as for shop jobs.

Read MoreShop Taps into Versatility, Time and Cost Savings

Standardizing on one, general-purpose tap for its diverse mix of jobs has helped this shop reduce inventory, costs and downtime.

Read MoreDoing More with a Live-Tool Lathe

A CNC lathe with live-tool capability can save time by milling and turning a part in the same setup.

Read MorePull Boring Highlights the Capability of Deep Hole Making

Pull boring enables users to achieve remarkable straightness in deep holes. A variation of this technique is also effective when maintaining consistent wall thickness (in long, cast pipes, for example) is top priority.

Read MoreChipbreaking Inserts Improve ID Grooving

Iscar says its Cut-Grip inserts are suitable for ID grooving and feature an N-type chipformer for OD turning of “problematic” metals.

Read MoreBallnose Cutters Increase Machining Performance

Ingersoll’s Finish-Ball Rush ballnose cutters are designed to increase machining performance.

Read MoreSolid Carbide Drills Improve Chip Flow, Evacuation

Seco Tools’ Feedmax -N solid carbide drills are designed for high-performance drilling in aluminum and nonferrous materials.

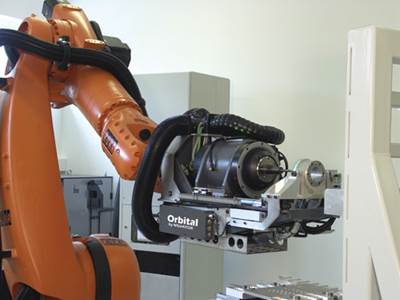

Read MoreEffective Hole Making Via Robotic Orbital Drilling

New technology may enable robotic drilling to be more commonplace in machine shops by overcoming the issue of limited robot rigidity.

Read More