-

SPONSORED

-

SPONSORED

Cutting Tools

Job Shop Finds Its Niche With The Help Of Tapping Machines

The metalworking job shop market can be illustrated as a pyramid. At the base of the pyramid is the largest segment of the discrete parts manufacturing business.

Read MoreThe Real-World Economics Of High-Performance Drilling

To determine true cost, consider the total life of the drill.

Read MoreRigid Tapping--Sometimes You Need A Little Float

One of the most common methods of tapping in use today on CNC machines is 'rigid tapping' or 'synchronous feed tapping.' A rigid tapping cycle synchronizes the machine spindle rotation and feed to match a specific thread pitch. Since the feed into the hole is synchronized, in theory a solid holder without any tension-compression can be used.

Read MoreHeavy-Duty Hole Making

A modular drilling and boring system has changed this oilfield product manufacturer's holemaking operations.

Read MoreDeep Thinking

A job shop that specializes in gundrilling points out the special requirements of machining deep holes.

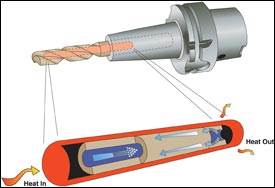

Read MoreDrilling Dry With A Heat Pipe

It's widely known that hole making is, by a significant margin, the most frequently performed process among metalworking operations. It's also among the most difficult operations to control from a thermal perspective.

Read MoreAnother Way To Square—Or Is It Perpendicular?—It Up

There are a number of tools available for shop personnel to evaluate the right angle relationship between two surfaces. The basic machinist square has a number of variations, the most common being the hardened steel square used to check right angles and set up milling and drilling machines.

Read More