-

SPONSORED

-

SPONSORED

Machines

Grinding Machine Incorporates Robot Pallet Loader

J. Schneeberger鈥檚 Gemini NGM production grinding machine is designed to maximize capacity in a compact footprint.

Read MoreRobotic Polishing of Turbine Engine Blades

Testing explores an airfoil finishing alternative to loose-abrasive polishing.

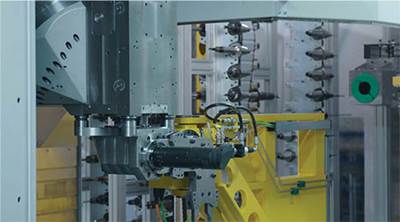

Read MoreMulti-Function Machines Turn, Mill and Grind

MCM offers a range of four- and five-axis machines, as well as multitasking machine models that can turn, mill and grind.

Read MoreTechnology for Turning on a Five-Axis Machine

A turning tool adapter that mounts to the MCT five-axis machine isolates the main spindle bearing from the shock of turning operations.

Read MoreAdditive Manufacturing’s Assist to ID Grinding

By addressing a long-standing coolant-delivery problem, an additively grown nozzle enhanced the effectiveness of ID grinding in a complementary role.

Read MoreShifting from Manual to Automatic

By partnering with its suppliers as a knowledge resource, this job shop made a successful transition from manual to CNC thread grinding, raising productivity and attracting new business with its increased capabilities.

Read MoreVMC Improves Shop’s Flexibility, Efficiency

RDM Manufacturing Precision CNC needed to improve its equipment flexibility to keep up with its large variety of clients. Investing in a VMC from SMTCL enabled the shop to achieve higher metal removal rates and better surface finish to better deal with demand.

Read MoreSlant-Bed Lathe Uses Bar Feeder, Gantry Loader for Automated Parts Processing

Chevalier’s FBL-200 rigid CNC slant-bed lathe is a fully automated, single-setup, parts processing machining system for mixed-volume, short runs or dedicated high-volume applications.

Read MoreHMC Accurately Machines Large Parts

The GE590H, Enshu鈥檚 largest horizontal machining center, is designed for large-part applications that demand both high-volume metal removal as well as precision.

Read MoreVMC Delivers High Rapid Traverse Rates

SMTCL Americas introduces its VMC1100B vertical machining center, which features a 12,000-rpm direct-drive spindle with 30-hp peak performance, 290-psi delivery of coolant through the spindle and a 24-position toolchanger.

Read More