Machines

Multitasking Turning Center Offers High Speed, Rigidity

Methods Machine ToolsŌĆÖ Nakamura-Tome WT-150 II eight-axis, multitasking turning center features opposed twin-spindle, two-turret construction for increased speed and rigidity.

Read MoreAuto EDM Wire Changers Compete at the High End

Automatic EDM wire-change capability can improve efficiency and reduce costs for high-end tool and die work, especially parts with small internal radii.

Read MoreShop Capitalizes on Water Over Wire

Two abrasive waterjet systems from Omax provide a cost-effective alternative to wire EDM and enable this shop to take on new work.

Read MoreCell’s Benefits Derive From Sum of Its Parts

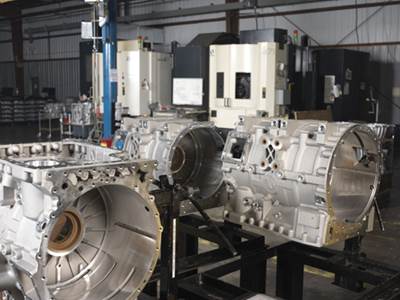

This shop’s experience with implementing a cell consisting of four robot-fed HMCS demonstrates that success depends on more than automation alone.

Read MorePump, Motion System Expand Waterjet Possibilities

Two Mitsubishi waterjets from MC Machinery Systems equipped with 125-hp, 90,000-psi pumps from KMT Waterjet Systems enable this manufacturer to cut thicker material faster and more accurately.

Read MoreCompact Multitasking Machine Provides Large-Component Capacity

The Mazak Integrex j-400 provides multitasking capabilities for processing large and complex components.

Read MoreSwiss-Turns Meet Part Variation Needs

REM Sales offers the Tsugami B0125 and B0205 Swiss-type automatic lathes.

Read MoreTwin-Spindle CNC Chucker Cuts Production Time

Muratec USA, a subsidiary of Murata Machinery, offers the MW120GT twin-spindle CNC chucker.

Read MoreSidehead Offers Optimum Angle for Turning Tall, Flanged Parts

A sidehead option for MagŌĆÖs vertical turning centers (VTCs) uses a 250-mm-square (10") ram to deliver 34,000-N (7,600-lbs) thrust from the optimum angle to efficiently turn tall or flanged parts in vertical orientation.

Read MoreWire EDM Built for Rigidity

The AQ400L wire EDM from Sodick features X-, Y- and Z-axis travel of 15.75” x 11.81” x 9.84” and ceramic components that increase machine rigidity.

Read More