-

SPONSORED

-

SPONSORED

-

-

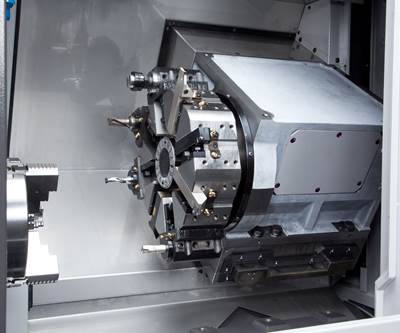

Turning Machines

Five Live Centers for Five Applications

It is vital for a shop to select the right machine tool components for the right job, and live centers for lathes are no exception.

Read MoreTwo-Axis Lathe Features Highly Rigid Construction

Tsugami/Rem Sales offers the Tsugami M08J, an highly rigid two-axis turning center with a manual tailstock, programmable quill and A2-6 spindle nose.

Read MoreSlant-Bed Lathe Provides Rigidity, Stability, Precision

IMTS 2018: Racer Machinery International is displaying its Standard Modern CNC S-22 slant-bed lath, developed using hand-scraped surfaces, a built-in slant that offers more rigidity, thermal stability and precision.

Read MoreBuying a Lathe: Slant-Beds and Multitasking Configurations

What are some variations on the basic lathe configuration? This can be helpful to review when considering the purchase of a new turning machine.

Read MoreTurning Center Reduces Setup Time

IMTS 2018: Hwacheon’s C2 multi-process turning center with Y- and C-axis control can manufacture parts with complicated shapes in a single chucking operation.

Read MoreCNC Lathe Designed for Heavy Materials

IMTS 2018: Kingston Machine’s CNC CX lathe is designed for cutting long and heavy workpieces for the energy, mining, textile, paper and transportation industries.

Read MoreSwiss-Type Lathe Can Also Operate as a Chucker

IMTS 2018: Tsugami/Rem Sales will feature the SS38MH-5AX, a 38-mm chucker-convertible, B-axis sliding headstock lathe that performs full five-axis simultaneous machining.

Read MoreVertical Lathe's Hydrostatic Rams Contribute to Better Finishes

IMTS 2018: Fives Giddings & Lewis is displaying the V 1600, a mid-range 1,600-mm table vertical lathe from the V series product line.

Read MoreBuying a Lathe: Spindles and Tailstocks

A key consideration when buying a new turning machine involves its spindle. Here’s an overview of what you need to know.

Read MoreWhat Is Single-Lobe Peeling?

A manufacturer of large turn-mill machines has developed a bar-peeling process to complete large, progressive cavity pump rotors in one setup.

Watch