-

SPONSORED

-

SPONSORED

Workholding

Quick Change Workholding For Hard-To-Hold Parts

This pwer chuck features direct transmission of the piston force to the jaws in the area of the jaw guides. The axial actuating force is transmitted to the jaws without major friction loss.

Read MoreMaking The Most of Modular Fixturing

Modular fixturing makes sense for this manufacturer, whether it's machining one- or two-of-a-kind parts for its custom machine tools or larger quantities for its contract machining business.

Read MoreManual Pallet Changers Bring Agility To The Shop

Continually searching for ways to reduce workpiece cost and to improve its responsiveness to customer demands, V-Line recently discovered how a manually operated pallet changing system could make a significant contribution to meeting its continuous improvement goals.

Read MoreConcentric Clamps Hold Down Setup Time

A problem for many shops is that workpiece blanks vary from one to another. This is especially true with molded part blanks such as castings and forgings. These variations require some flexibility from the workholding device.

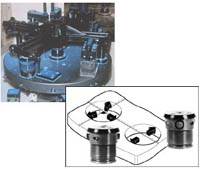

Read MoreAutomatic Pallet Systems Increase Production And Quality

These pallet changer systems not only improved this tooling manufacturer's labor situation, but they managed to increase their production as much as 600 percent on some of its indexable cutting tool products.

Read MoreWorkholding Provides Maximum Setup Versatility For Unattended Machining

JEM Technical Marketing (Long Lake, Minnesota) manufactures a broad line of custom manifold assemblies used in all types of fluid power applications such as off-highway vehicles, tractors and road graders.

Read MoreIs It Time For Bar Fed Machining Centers?

When we think of bar feeders, usually they are associated with turning operations. Recently though, some builders have developed machining centers that incorporate bar fed raw stock. It’s an interesting idea for the right applications and one that can economically reduce material handling and fixturing requirements on machining centers. Here’s a look at how they work.

Read MoreTurning Off-Center Diameters In One Setup

In the past, turned parts with one or more off-center hubs could not be machined in one chucking on a lathe or turning center. Typically, the part had to be rechucked in a special fixture to center the eccentric portions for turning. Parts with more than one eccentric hub required additional refixturing.

Read MoreWorkholding With A Vacuum Chuck

An aerospace machine shop meets a special need by using a vacuum chuck.

Read MoreManufacturing Cell Boosts Profits And Flexibility

One machine shop owner in old New England, not far from where Paul Revere made his famous ride, saw a tight labor market as a call to revolutionize his company.

Read More