-

SPONSORED

-

SPONSORED

-

Workholding

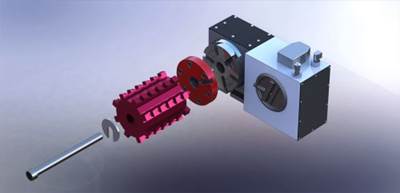

Quick-Change Fixture System Designed for Rotary Tables

Laser Tools Machining, a division of Laser Tools Co. Inc., offers the Gravestone, a quick-change fixture system designed to fit onto a rotary table or computer-driven indexer.

Read MoreID Clamps Offer Precision Clamping with No Interference

Self-centering ID clamps from Carr Lane Manufacturing simultaneously locate and clamp from the inside of an existing hole or slot in a workpiece, leaving the entire outer surface clear for machining.

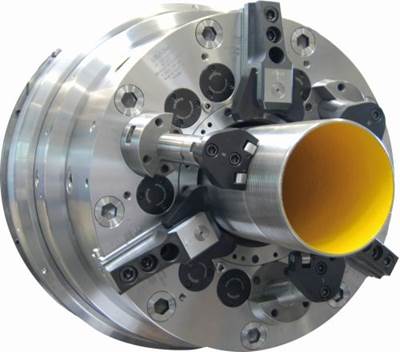

Read MoreChucks Enable Efficient Machining of Pipes

Designed specifically for the oil and gas industry, Röhm Products of America’s LVE chuck system enables manufacturers to quickly and efficiently process long, large pipes as well as associated pipe couplings and connectors.

Read MoreAir Chucks Offer Extended Stroke

Samchully Workholding’s PAC series of extended-stroke Mega Bore air chucks are designed for pipe and tubular applications.

Read MoreVideo: Automation Inside the Workzone

What is automation? Not just a robot. Technology for holding, moving and measuring the part inside the machine can also achieve considerable time and labor savings.

WatchWhy Not Lights-Out Inspection?

A contract shop in Connecticut is developing a process to enable its new CMM to inspect multiple parts unattended, thereby minimizing the impact that part measurement has on the company’s bottom line.

Read MoreWorkholding That’s on Point

A pin-based workholding system quickly accommodates workpieces of any shape.

Read MorePeople are Part of the Process for Machining Inconel

A Tacoma shop describes its winning strategy for efficient machining of Inconel. That strategy includes careful choices of cutting tools and cutting parameters. It also includes a healthy breakfast.

Read MoreSealed Holder Protects Chucks from Debris

Erowa will present its ITS 50 Holder C, designed to protect chucks against contamination such as copper chips, graphite dust or fine HSC chips during manufacturing processes.

Read MoreWorking Toward Lights-Out Inspection

Contract shop PDQ is developing a process to enable its new CMM to inspect multiple parts unattended, thereby minimizing the impact that part measurement has on the company’s bottom line.

Read More