-

SPONSORED

-

SPONSORED

-

SPONSORED

-

Products

Welding System Algorithmically Corrects Beginning Welder’s Arc

Esab introduces its Rebel EMP 215ic, a 120-230V, CC/CV welding system that offers multi-process arc performance, location flexibility, lightweight portability and an operator interface intended to make it easy for beginners to use.

Read MoreCustom Top Jaws Hold Workpiece ID, OD or Both

Special top jaws from Dillon Manufacturing can grip a workpieceŌĆÖs ID, OD or a combination of both, to suit a variety of workholding applications.

Read MoreAutomated Cell Handles Gears during Heat-Treatment Process

ABB Robotics has developed a robotic gear-handling cell to transfer gears between alloy trays and baskets in the heat-treatment process that transforms ŌĆ£greenŌĆØ gears into ŌĆ£hardŌĆØ gears.

Read MoreGearbox Software Performs Design Durability Evaluations

Comet is developing a suite of SimApps, or simulation applications, for gearbox design and manufacturing.

Read MoreSlant-Bed Lathe Uses Bar Feeder, Gantry Loader for Automated Parts Processing

Chevalier’s FBL-200 rigid CNC slant-bed lathe is a fully automated, single-setup, parts processing machining system for mixed-volume, short runs or dedicated high-volume applications.

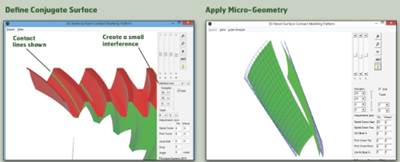

Read MoreBevel Gear Software Eliminates Need for Dedicated Machine

Dontyne SystemsŌĆÖ Bevel Software Production Suite has been expanded to include transmission error with load and roll-check analysis.

Read MoreDeburring Machine Features Self-Cleaning, Sanding

ArkuŌĆÖs EdgeBreaker deburring machine is designed to remove thick slag and heavy burrs as large as 3 mm on steel, copper, aluminum, titanium and alloyed parts measuring 80-mm thick and 1,300-mm wide.

Read MoreHMC Accurately Machines Large Parts

The GE590H, EnshuŌĆÖs largest horizontal machining center, is designed for large-part applications that demand both high-volume metal removal as well as precision.

Read MoreGrinding Lube Filtration System Adaptable to Changing Production Requirements

Available from Oelheld, Vomat’s FA series of grinding lubricant filters promotes cleaner lubricant, resulting in reduced need for replacement; longer machine uptime; and tool, filter and lubricant cost savings.

Read MoreVMC Delivers High Rapid Traverse Rates

SMTCL Americas introduces its VMC1100B vertical machining center, which features a 12,000-rpm direct-drive spindle with 30-hp peak performance, 290-psi delivery of coolant through the spindle and a 24-position toolchanger.

Read MoreLow-Temp Blackening Process Protects Gears for Storage, Shipment, Startup

Birchwood Technologies says that its Tru Temp black oxide process meets demand by gear component manufacturers for an in-house metal finishing process that provides break-in lubricity, robust corrosion protection and galling resistance on critical components.

Read MoreVMC Eliminates Backlash in Mold Production

Sharptech Precision Machinery’s Super 1320 vertical machining center is designed for mold processing.

Read More