-

SPONSORED

-

SPONSORED

Cutting Tools

Chucks And Arbors Designed For Holding Thin-Walled Parts

The Conform-A-Chuck and Conform-A-Arbor workholding solutions are designed to adapt to an out-of-round OD or ID and securely grip that diameter to enable boring, honing, grinding or other machining operations without changing the original free-state shape of the part. These workholding solutions are suited for the machining of thin-walled parts such as automotive smog control air pump rotors, gas turbine parts, thin-wall tubing and cylinder liners for diesel engines. The Conform-A products rely upon a plastic material called Hydra-Fibre.

Read MoreDual-Column Bandsaw

The C-420NC programmable dual column band saw accommodates round material ranging to 16. 5″ in diameter and 16. 5″ × 16.

Read MoreExpanded Line Of Miniature Deburring Brushes

According to the company, miniature deburring brushes can automate the removal of burrs and the production of an edge radius on small-dameter holes, saving time and money while improving product quality and consistency. Filament choices include carbon steel, stainless steel, brass, nylon and natural to provide the optimum finish on a variety of base materials. The miniature deburring brushes are available in a diamond-abrasive-filled nylon filament.

Read MoreHob And Shaper Cutter Aids Sharpening Of Reliefs

Star SU manufactures Sykes-style herringbone cutters and offers tool resharpening machines for sharpening the face and relief lip on the herringbone cutters. The PTG-1 hob and shaper cutter resharpening system includes software for the special relief grinding of Sykes cutters. This five-axis grinding machine features a Num Axium CNC control, Numrotoplus software, integrated automatic part probing, automatic wheel probing, and on-board wheel dressing.

Read MoreCarbide Indexable Insert Chamfering Tool

The Cinch carbide insert chamfering tool from Fitz-Rite Products uses a square ANSI standard insert and is available in 60-, 82-, 90- and 120- degree included angles. The compact, rigid design enables the user to chamfer holes with diameters as small as 1/4" while using the high rpms and feed rates. Also available in the double-angle configuration, the tool can be used to chamfer both the top and the bottom of holes with diameters as small as 21/32".

Read MoreVideo: Understanding The Role Of L:D Ratio In Micromachining

When milling with tiny tools, changing the length-to-diameter ratio can significantly change the cutting parameters it is possible to achieve.

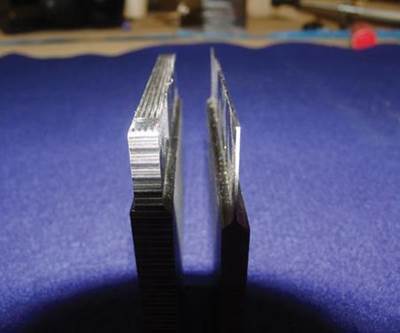

Read MoreHow To Machine Aircraft Titanium: The 8-To-1 Rule For Finishing Walls And Ribs

Part of a series of articles on more efficient machining of pockets in titanium parts, this article makes the case for a tool with many cutting edges, and describes how best to apply it.

Read MoreHow To Machine Aircraft Titanium: Getting The Metal Out

Part of a series of articles on machining pockets in titanium parts, this article describes various options for roughing the hard metal efficiently.

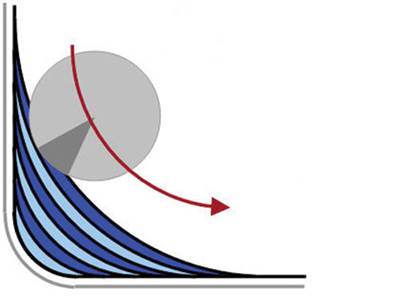

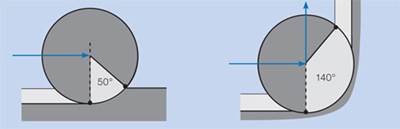

Read MoreHow To Machine Aircraft Titanium: Plunge And Sweep For Finishing Corners

Part of a series of articles on more efficient machining of pockets in titanium parts, this article describes an effective approach to finishing internal corners.

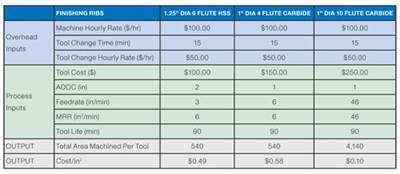

Read MoreHow To Machine Aircraft Titanium: Pricing The Process Instead Of The Tool

Part of a series of articles on more efficient machining of pockets in titanium parts, this article describes the importance of considering all of the costs that are affected by the choice of cutting tool.

Read More