-

SPONSORED

-

SPONSORED

Cutting Tools

Finishing A Pocket Floor In Titanium

Machining animation from Boeing illustrates effective techniques for titanium workpieces. This simulation also shows finishing of the floor of the pocket.

WatchFinishing Walls In Titanium

Machining animation from Boeing illustrates effective techniques for titanium workpieces. This video shows material machined out of the corners prior to finishing.

WatchPlunge-And-Sweep For Finishing Corners

Machining animation from Boeing illustrates effective techniques for titanium workpieces.

WatchInsert Provides Long Life, Short Cycle Times

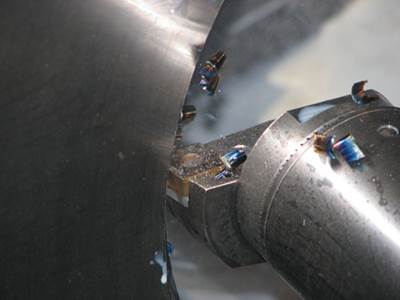

Novatek, a manufacturer of diamond products used in the oil and gas, mining, construction and other industries, needed to reduce both costs and production time on a job involving very large workpieces. The Tiger-Tec black and gold WPP10 insert from Walter USA, which聽features an aluminum oxide coating designed to prolong tool life at high surface footages, helped the company increase feeds and speeds and create smaller, more manageable chips.

Read MoreTool Storage System Standardizes Setup

Faced with time-consuming setups and tool handling, hydraulic manifold manufacturer Apollo Machinery set out to develop its own compact tool storage and tracking system. In the process, the shop not only increased its own efficiency, but also developed a product that it says could set a standard for CNC machine setup.

Read MoreLaser Edge Preparation Improves Diamond Tool Performance

A cutting tool manufacturer uses seven-axis laser machining聽to create contoured, 3D chipbreaker geometries for its聽diamond-tipped inserts and tools.

Read MoreEnd Mills Feature Minimal Chatter

SGS Tool Company introduces a high-performance end mill that provides precision performance and high production rates with minimal chatter. The end mills feature variable pitch fluting geometry that provides improved chatter suppression, longer tool life, better surface finishes and high productivity rates, the company says. Manufactured with a rigid construction using certified premium micro-grain carbide, the end mills also deliver reduce harmonics and reduced radial side deflection allowing for improved side wall straightness.

Read MoreHigh-Performance Coolant-Through Tooling

Seco Tools offers Jetstream Tooling, a line of high performance tools designed to deliver coolant directly at the insert cutting edge for better chip control and long tool life. The high cutting speed and feed rates are said to be maintained across coolant pressures ranging from 70 to 5,000 psi for materials including titanium alloys, nickel-chromium, aluminum and steel alloys, and stainless steel. Coolant is applied through the tooling nozzle at high pressure, close to the cutting edge, cooling the work area and producing smaller, hard, brittle chips.

Read MoreAdjustable Milling Cutters

A new family of high speed milling (HSM) adjustable end mills and face mills from Iscar are said to improve milling of aluminum, non-metallics, cast iron and hardened steel, especially in automotive and aerospace applications. The dynamically balanced cutters are designed to work with polycrystalline diamond (PCD) or cubic boron nitride (CBN) inserts, which provide cutting edge protection and quality surface finishes, the company says. They also accommodate standard HSM-rated Helido 2000 carbide inserts.

Read MoreDual-Feature Center Drill

The CrazyDrill Twicenter from Mikron Tool features two integrated coolant ducts and a double cutting point. The integrated ducts supply coolant directly to the drill鈥檚 cutting edge, so no additional external cooling is needed. Bringing the coolant to the cutting edge is a challenge for drilling鈥攁nd consequently when centering鈥攊n difficult-to-access places.

Read More