-

SPONSORED

-

SPONSORED

-

-

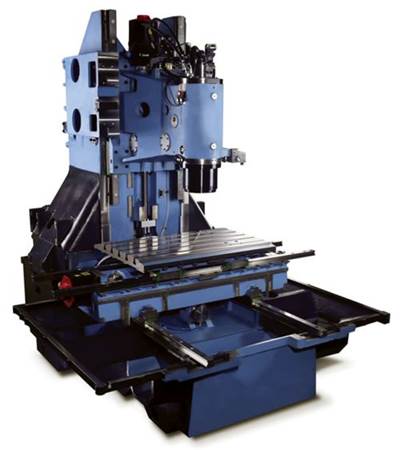

Vertical Machining Centers

What Makes for an Effective, Production-Oriented VMC?

Extended VMC cycle times due to modest spindle performance and slow non-cutting functions can increase costs for high-volume applications. However, new VMC offerings can minimize cycle times while maximizing competitiveness for production work.

Read MorePrecision Micromachining Center for High Speed Machining

Makino says its iQ300 precision micromachining center incorporates the latest advances in machine and spindle design, thermal control and precision.Â

Read MoreOtherworldly Precision

A contract shop produces critical parts for the Curiosity rover that will soon depart for Mars.

Read MoreTransforming Industrial Robots into Precision Machine Tools

Robots fitted with an adaptive control system get real-time course corrections throughout the machining cycle.

Read MoreVMC Combines Speed, Power

The VC430 VMC from Doosan features a 25-hp motor that generates as much as 12,000 rpm at the spindle and 123.6 foot-pounds of torque.

Read MoreVMCs Designed for Heavy, Fast Cutting

Distributed by Fortune International, Victor Taichung Machinery’s Vcenter-A series of VMCs accommodate both heavy cutting at low rpm and high speed machining.

Read MoreDoosan Makes a Power Play

The South Korean builder is directing its focus toward rigid machine platforms capable of heavy cuts in tough materials.

Read MoreRigid, Reliable Machines Aid In-House Production

This plastics industry manufacturer relies on machines from Toyoda to produce twin-screw extruders and other production equipment in-house. This strategy saves the company money and enables it to respond flexibly to changing market conditions, among other benefits.

Read MoreThe In-House Advantage

A shop that introduced its own product realizes the advantages of designing and machining a part under the same roof.

Read MoreVMC Provides High Accuracy

Kitamura’s Mycenter-3XG VMC offers positioning accuracy measuring ±0.000079" and repeatability of ±0.000039". All mounted surfaces requiring assembly are hand scraped to provide full surface contact and proper alignment for long-term reliability, peak performance and accuracy, the company says.The machining center’s thick walls and ribbed box-type, Meehanite-cast construction, coupled with solid box guide ways on the X, Y and Z axes, are designed to ensure quality and rigidity.

Read More