-

SPONSORED

-

SPONSORED

-

-

Vertical Machining Centers

VMC Developed for Die and Mold Industry

YCM Americas offers the NTV158B, a high-efficiency, T-base VMC for die and mold applications.

Read MoreVMC Features Built-In Spindle for High-Speed Cutting

The Hwacheon Sirius UL+ VMC is equipped with a 20,000-rpm, built-in spindle for high-speed cutting.

Read MoreVMC Eliminates Vibration for Micromachining Applications

Makino’s V22 VMC is designed to eliminate vibration, rotational deflection and thermal distortion to ensure precision, accuracy, reliability and stability

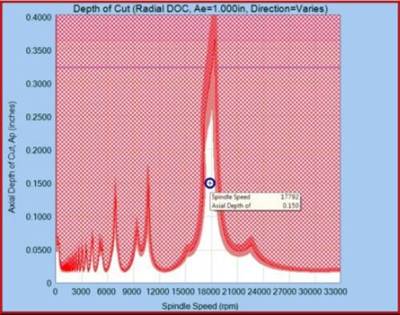

Read MoreWhat Your Handbook Isn’t Telling You

Tony Schmitz, professor at the University of North Carolina at Charlotte, gives a presentation on machine tool dynamics. Learn the role that this concept plays in realizing your optimal machining center performance.

Read MoreVMCs Support Heavy Machining

YMT's QV-179 and 209 VMCs feature a heavily ribbed Meehanite casting for stability.

Read MoreVMCs Engineered for Precision Mold Making

Designed specifically for precision mold machining, Hyundai Wia’s Hi-Mold series of high speed VMCs offer a rigid bridge-type design that is said to minimize heat generation.

Read MoreA Big-Picture View of Micromachining

Matrix Tooling makes injection molds for components that have features you cannot see.

Read MoreAutomated VMC Fills Capacity Gap

A new Feeler VMC from Methods Machine Tools has not only met this manufacturer’s need for additional capacity, but also taken on more work than initially expected.

Read MoreUniformity Paves the Way for Flexibility

Standardizing on one brand of machines provides the flexibility this firearm component manufacturer needs to accommodate a variety of custom component designs.

Read MoreDouble-Column VMC Offers High Rigidity

The FVM-3016DCL double-column VMC from Chevalier features a table size ranging from 126" Ă— 57" to 165.4" Ă— 57" with a table load ranging from 14,330 to 17,637 lbs.

Read More