-

SPONSORED

-

SPONSORED

Cutting Tools

Aligning Critical Bores

A chuck/fixture combo enables a gage maker to drill perfectly aligned holes in dial indicator housings.

Read MoreMachines For Today's Toolrooms

If there's room for improvement in any NC program, this shop addresses the problem once and for all by making the correction in the postprocessor.

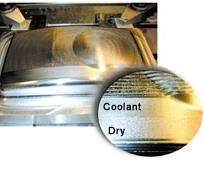

Read MoreWhere Dry Milling Makes Sense

Liquid coolant offers advantages unrelated to temperature. Forced air is the fluid of choice in this shop...but even so, conventional coolant can't be eliminated entirely.

Read MoreWinner By A Nose!

Wiper technology is designed to improve surface finish in machining applications. It involves an insert with a flat. As the 'wiper' passes through the cut, it smoothes the surface.

Read MoreVacuum Pump Maker Finds Innovative Ways To Reduce Manufaturing Costs

With new tooling, this manufacturer was able to mill housings at 3,000 sfm and a feed rate of 230 ipm. Cutting time dropped from 20.68 minutes to 12.74 minutes, a savings of nearly 40 percent.

Read MoreTool Monitoring May Be An Essential Part Of Unattended Machining

To take advantage of unattended machining, shops will most likely be forced to utilize some type of tool monitoring system.

Read MoreImproved Tool Changeover Time And Increased Tool Life For Turret Punching

A desire to reduce CNC punch press tool setup time and shorten product deliveries motivated this shop to invest in a new tooling system.

Read MoreTrends That Drive Cutting Tool Development

Cutting tools have highly engineered coatings and geometries for all types of manufacturing methods and materials.

Read MoreSizing With Tool Nose Radius Compensation

Most turning center users use wear offsets for the purpose of holding size over the course of a production run. And with most of the tools used on turning centers (turning tools, boring bars, grooving tools, among others), all production run sizing should be done with wear offsets.

Read MoreDon't Touch That Tool

Tool measurement is critical to the metalcutting process. Exact knowledge of a cutter鈥檚 length, diameter, even profile, and the ability to measure and monitor these dimensions over time, can reduce variability and help optimize the process. Here鈥檚 a look at how non-contact tool measurement and breakage detection benefit your metalcutting process.

Read More