-

SPONSORED

-

SPONSORED

Cutting Tools

Multiple Layer Coatings Keep Microcracks From Destroying Inserts

One reason why cutting tool inserts fail is that microcracks start in the top coating and work down to the substrate, eventually exposing the unprotected substrate to the damaging forces at work during a machining process. Slowing the formation of these microcracks and preventing them from reaching the substrate should therefore increase insert life.

Read MoreExtending The Range Of PCBN

Thicker inserts and a wider variety of styles are allowing PCBN to be applied to a growing range of hard, ferrous applications.

Read MoreOhio Manufacturer Cuts Milling Time By 75 Percent

Oren Elliott Products, Inc. is located in Edgerton, Ohio near the Indiana border. It is a large North American supplier of air-dielectric variable capacitors, which are used in such diverse applications as magnetic resonance imagery equipment, mass spectroscopy equipment, silicon chip plasma etching and deposition devices, plus surface-to-air missile guidance systems.

Read MoreIt's A Machine Tool Robot

This machine has a dual identity. It looks like an industrial robot. In some applications, such as assembly, it is. However, put a spindle and cutting tool on the end of this five-axis machine and it becomes a machining and drilling center. The inherent stiffness of the machine's tripod design makes it accurate enough to machine aerospace and automotive applications.

Read MoreAre You Turning Fast Enough?

Let's face it. When most shops go looking for process improvements, turning is seldom at the top of the list. Sure, many shops these days are doing fine work in such areas as reducing lathe setup, combining milling and turning operations on a single machine, and automating workpiece handling functions. But for all the talk of high speed machining and other milling and drilling process improvements, precious little of that kind of thinking is being applied to the turning process itself.

Read MoreBig Boring On Smaller Machines

This modular boring system lets you bore holes up to eight inches in diameter on machining centers with 40-taper spindles.

Read MoreThe Fast Track To High Speed Drilling

Drill more productively by making a few strategic changes to the process. Those same changes may also let you drill dry.

Read MoreThe Case For Cutting Tool Standardization

It's possible to increase overall machining efficiency at the same time you decrease cutting tool inventory. Here's how.

Read MoreThe Case For Optimized Inserts

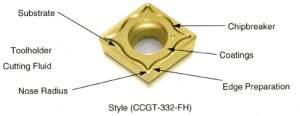

A carbide insert is an engineered system consisting of substrate, coating, geometry and other components designed to work together. Insert manufacturers are getting very adept at optimizing this system and matching it to a given application.

Read MoreFine Pitch Cutter Increases Milling Productivity

This 120 year-old manufacturer to update its manufacturing processes and expand its product offering so it could become a sole-source supplier for its customers in the steam industry.

Read More